Abouts

Current Location:Index >> Abouts >> company profile

Current Location:Index >> Abouts >> company profile

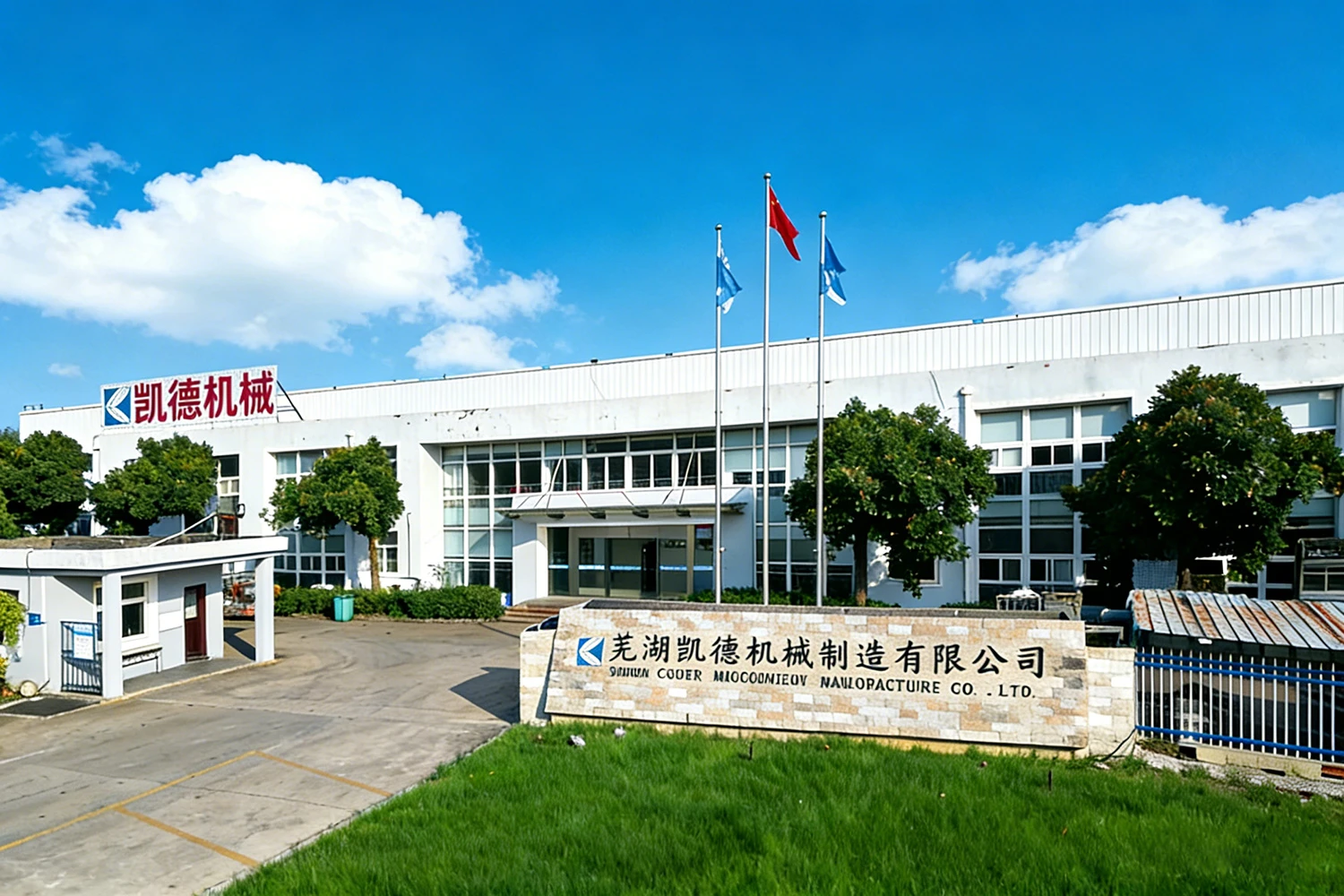

Wuhu Kaide Machinery Manufacturing Co., Ltd. was established in February 2004. It is a national high-tech enterprise and specialized new small and medium-sized enterprise that integrates scientific research, design, production, sales, and technical services. The core focus is on the two business modules of "automotive core connectors+precision inspection fixtures", providing high-precision and highly reliable supporting services for the passenger car, commercial vehicle, and new energy vehicle markets from component production to testing and assembly. With strict quality control and technological innovation, it has become a high-quality partner in the automotive manufacturing field.

Core Main Business and Product System

The company is guided by the core needs of automobile manufacturing, with products covering two major scenarios of "component production+testing and assembly assistance", combining standardized mass production and customized adaptation capabilities, accurately matching customer production and quality control needs:

1、 Automotive core connectors (main products)

Focusing on key parts of the power system and chassis system, providing core support for vehicle structural stability and operational safety:

-Automotive steering knuckle: the core load-bearing component of the chassis steering system, using high-precision machining technology and high-strength alloy materials, with strong impact resistance and dimensional stability, suitable for passenger cars and light commercial vehicles, ensuring steering accuracy and driving safety.

-Structural connection plate: Customized production of structural components connecting various parts of the body and chassis, with integrated molding process to ensure strength, meet assembly fastening and long-term fatigue resistance requirements, and adapt to complex assembly scenarios of different vehicle models.

-Engine/motor bracket: the core load-bearing component of the power system, using a composite design of "metal+shock-absorbing material", which not only fixes the engine/motor, prevents displacement, but also suppresses vibration propagation and reduces interior noise. It is suitable for various types of engines in traditional fuel vehicles and electric motors in new energy vehicles.

-Customized connectors: Based on customer needs, we develop and produce exclusive connectors for powertrain and chassis systems, providing full process services from design optimization, sample testing to large-scale production.

2、 Automotive specific gauges and fixtures (supporting products)

Develop and produce specialized auxiliary equipment around the demand for "precise detection+efficient assembly" of automotive components, ensuring component quality and production efficiency:

-Specialized inspection tools for automotive parts: For core connectors such as steering knuckles, connecting plates, engine/motor brackets, customized size inspection tools (such as aperture inspection tools, contour inspection tools) and form and position tolerance inspection tools (such as parallelism inspection tools, coaxiality inspection tools) are designed. High precision sensors and reference positioning structures are used, with a detection error of ≤ 0.005mm, which can quickly complete the compliance judgment of component size and accuracy, and is suitable for efficient quality inspection in mass production scenarios.

-Special fixtures for automobile production: covering two types of parts processing fixtures and assembly fixtures. Processing fixtures can fix workpieces such as steering knuckles and brackets to ensure accurate dimensions during machining; The assembly fixture adapts to the assembly of connectors with the vehicle body and power system, achieving fast positioning, stable clamping, reducing assembly deviation, improving production efficiency and assembly consistency. It can be customized according to the customer's production line rhythm and workpiece specifications.

Core advantages of the enterprise

-Dual compliance with technology and standards: With multiple patents, the connectors and fixtures comply with standards such as ISO 8092 and GB/T 28046, and have passed the IATF 16949 automotive industry quality management system certification, with key indicators reaching the industry's advanced level.

-Collaborative capability of "product+matching": It can provide synchronized production of connectors and corresponding fixtures to avoid compatibility issues with products from different suppliers, simplify the procurement process for customers, and adjust the fixture parameters according to connector design to improve overall matching efficiency.

-Widely adaptable to the market: The product is suitable for traditional fuel vehicles and new energy vehicles (optimized for high-pressure and lightweight needs), and has been matched with mainstream car companies such as Chery, Geely, Changan, BAIC, Xiaopeng, etc. It is exported to Southeast Asia, Europe and America, covering multiple sub models, and has the ability to achieve large-scale production and rapid delivery.

-Stable operation guarantee: Registered capital of 5 million yuan has been fully paid in, with 50-99 employees (67 insured), complete equipment and testing system, sound welfare, stable production and operation, and can meet customers' long-term supporting needs.

2004Year

The company was established and has rich industry experience100Unit

Professional production and testing equipment80Staff

Enterprise employees and technical R&D personnel1000Companies

Common choice for customers

SCROLL

SCROLL Phone:+86 553 5312335

Phone:+86 553 5312335 Fax:+86 553 5314000

Fax:+86 553 5314000 Email:web@chinakaide.com

Email:web@chinakaide.com Address:No. 28 Fumin Road, Phase II, Jiujiang Development Zone, Wuhu City, Anhui Province, China

Address:No. 28 Fumin Road, Phase II, Jiujiang Development Zone, Wuhu City, Anhui Province, China Quick Navigation

Quick Navigation

Product Series

Product Series

Mobile Station QR Code

Mobile Station QR Code

Copyright© 2026 Wuhu Kaide Machinery Manufacturing Co., Ltd All Rights Reserved